主管:中国科学院

主办:中国科学院古脊椎动物与古人类研究所

出版:科学出版社

主办:中国科学院古脊椎动物与古人类研究所

出版:科学出版社

人类学学报 ›› 2024, Vol. 43 ›› Issue (05): 727-743.doi: 10.16359/j.1000-3193/AAS.2024.0023cstr: 32091.14.j.1000-3193/AAS.2024.0023

收稿日期:2023-08-08

修回日期:2023-11-21

出版日期:2024-10-15

发布日期:2024-10-10

通讯作者:

陈虹

作者简介:李尧,博士研究生,主要研究方向为旧石器考古、微痕研究。E-mail: liyao2021@zju.edu.cn

基金资助:

LI Yao1( ), CHEN Hong1(

), CHEN Hong1( ), XU Ting2

), XU Ting2

Received:2023-08-08

Revised:2023-11-21

Online:2024-10-15

Published:2024-10-10

Contact:

CHEN Hong

摘要:

为完整了解黑曜岩石制品在暗场与明场的使用痕迹特征,本文开展了黑曜岩打制实验,并使用这些石制品加工肉类、皮革、禾本科植物、木材、骨骼、鹿角、赭石等实验材料。实验结果显示:1)材料硬度会对痕迹组合特征产生重要影响。随着加工对象硬度的增高,片疤的尺寸逐渐变大;刃脊的磨圆和光泽由光滑向粗糙转变;线状痕出现由流畅型向间歇型或蕨叶型转化;2)刃角与动作也会对使用痕迹产生影响。切动作的光泽多呈微小且不连续状,但线状痕发育明显,并与刃脊平行或斜交;刮动作的光泽呈连续状,但线状痕发育较弱,并与刃脊垂直;3)加工时长对黑曜岩光泽痕迹的影响并不明显。本项研究系统观察了黑曜岩石制品加工的多种材料的痕迹特征,并与其他学者的结论进行了对比。本研究将为继续深入探讨我国东北与西藏地区的黑曜岩石制品的功能,以及该地区古人类的生存策略提供数据支持。

中图分类号:

李尧, 陈虹, 徐廷. 黑曜岩实验打制品使用后的痕迹特征[J]. 人类学学报, 2024, 43(05): 727-743.

LI Yao, CHEN Hong, XU Ting. Use-wear characteristics of the obsidian experimental artifacts[J]. Acta Anthropologica Sinica, 2024, 43(05): 727-743.

| 标本号ID | 类型Type | 刃角Edge angle | 硬度Hardness | 材料Materials | 动作Action | 阶段时长Times(min) |

|---|---|---|---|---|---|---|

| 001 | 琢背小刀 | 36 | 软性 | 猪肉 | 切 | 10, 15 |

| 002 | 端刮器 | 76 | 软性 | 鞣制麂皮 | 刮 | 5, 10, 20, 30 |

| 003 | 琢背小刀 | 49 | 软性 | 鞣制麂皮 | 切 | 10 |

| 004 | 琢背小刀 | 31 | 软性 | 干狗尾草 | 切 | 5, 10, 20, 30, 40 |

| 005 | 端刮器 | 76 | 中性 | 鲜柞木 | 刮 | 5, 10, 20, 30 |

| 006 | 琢背小刀 | 33 | 中性 | 鲜柞木 | 切 | 5, 10, 20, 30 |

| 007 | 琢背小刀 | 34 | 中性 | 干柞木 | 切 | 5, 10, 20, 30 |

| 008 | 琢背小刀 | 23 | 中性 | 干柞木 | 刮 | 5 |

| 009 | 端刮器 | 72 | 中性 | 干柞木 | 刮 | 10, 20, 30 |

| 010 | 琢背小刀 | 45 | 硬性 | 鲜猪肩胛骨 | 切 | 5, 10, 20, 30 |

| 011 | 刮削器 | 41 | 硬性 | 干牛骨 | 切 | 5, 10 |

| 012 | 端刮器 | 89 | 硬性 | 干牛骨 | 刮 | 5, 10, 20, 30, 40 |

| 013 | 琢背小刀 | 41 | 特硬性 | 鹿角 | 切 | 10 |

| 014 | 端刮器 | 70 | 特硬性 | 鹿角 | 刮 | 5, 10, 20, 30 |

| 015 | 刮削器 | 89 | 特硬性 | 赭石 | 刮 | 5 |

| 016 | 琢背小刀 | 20 | 多种物质 | 鲜猪肩胛骨 | 肢解剔肉 | 15 |

| 017 | 刮削器 | 84 | 特硬性 | 石锤 | 硬锤修理 | 0.16 |

| 018 | 刮削器 | 65 | 特硬性 | 石锤 | 修磨刃缘 | 0.16, 1 |

| 019 | 端刮器 | 68 | 特硬性 | 砂岩 | 磨制 | 20 |

| 020 | 石片 | 46 | 软性 | 皮革 | 切 | 20 |

| 021 | 琢背小刀 | 45 | 软性 | 干狗尾草 | 切 | 20 |

| 022 | 石片 | 62 | 中性 | 干柞木 | 刮 | 20 |

| 023 | 琢背小刀 | 70 | 硬性 | 干牛骨 | 刮 | 20 |

| 024 | 琢背小刀 | 55 | 特硬性 | 鹿角 | 切 | 20 |

| 025 | 刮削器 | 82 | 特硬性 | 赭石 | 刮 | 5 |

表1 实验标本微痕记录表

Tab.1 The recordings of microwear analysis of experimental samples

| 标本号ID | 类型Type | 刃角Edge angle | 硬度Hardness | 材料Materials | 动作Action | 阶段时长Times(min) |

|---|---|---|---|---|---|---|

| 001 | 琢背小刀 | 36 | 软性 | 猪肉 | 切 | 10, 15 |

| 002 | 端刮器 | 76 | 软性 | 鞣制麂皮 | 刮 | 5, 10, 20, 30 |

| 003 | 琢背小刀 | 49 | 软性 | 鞣制麂皮 | 切 | 10 |

| 004 | 琢背小刀 | 31 | 软性 | 干狗尾草 | 切 | 5, 10, 20, 30, 40 |

| 005 | 端刮器 | 76 | 中性 | 鲜柞木 | 刮 | 5, 10, 20, 30 |

| 006 | 琢背小刀 | 33 | 中性 | 鲜柞木 | 切 | 5, 10, 20, 30 |

| 007 | 琢背小刀 | 34 | 中性 | 干柞木 | 切 | 5, 10, 20, 30 |

| 008 | 琢背小刀 | 23 | 中性 | 干柞木 | 刮 | 5 |

| 009 | 端刮器 | 72 | 中性 | 干柞木 | 刮 | 10, 20, 30 |

| 010 | 琢背小刀 | 45 | 硬性 | 鲜猪肩胛骨 | 切 | 5, 10, 20, 30 |

| 011 | 刮削器 | 41 | 硬性 | 干牛骨 | 切 | 5, 10 |

| 012 | 端刮器 | 89 | 硬性 | 干牛骨 | 刮 | 5, 10, 20, 30, 40 |

| 013 | 琢背小刀 | 41 | 特硬性 | 鹿角 | 切 | 10 |

| 014 | 端刮器 | 70 | 特硬性 | 鹿角 | 刮 | 5, 10, 20, 30 |

| 015 | 刮削器 | 89 | 特硬性 | 赭石 | 刮 | 5 |

| 016 | 琢背小刀 | 20 | 多种物质 | 鲜猪肩胛骨 | 肢解剔肉 | 15 |

| 017 | 刮削器 | 84 | 特硬性 | 石锤 | 硬锤修理 | 0.16 |

| 018 | 刮削器 | 65 | 特硬性 | 石锤 | 修磨刃缘 | 0.16, 1 |

| 019 | 端刮器 | 68 | 特硬性 | 砂岩 | 磨制 | 20 |

| 020 | 石片 | 46 | 软性 | 皮革 | 切 | 20 |

| 021 | 琢背小刀 | 45 | 软性 | 干狗尾草 | 切 | 20 |

| 022 | 石片 | 62 | 中性 | 干柞木 | 刮 | 20 |

| 023 | 琢背小刀 | 70 | 硬性 | 干牛骨 | 刮 | 20 |

| 024 | 琢背小刀 | 55 | 特硬性 | 鹿角 | 切 | 20 |

| 025 | 刮削器 | 82 | 特硬性 | 赭石 | 刮 | 5 |

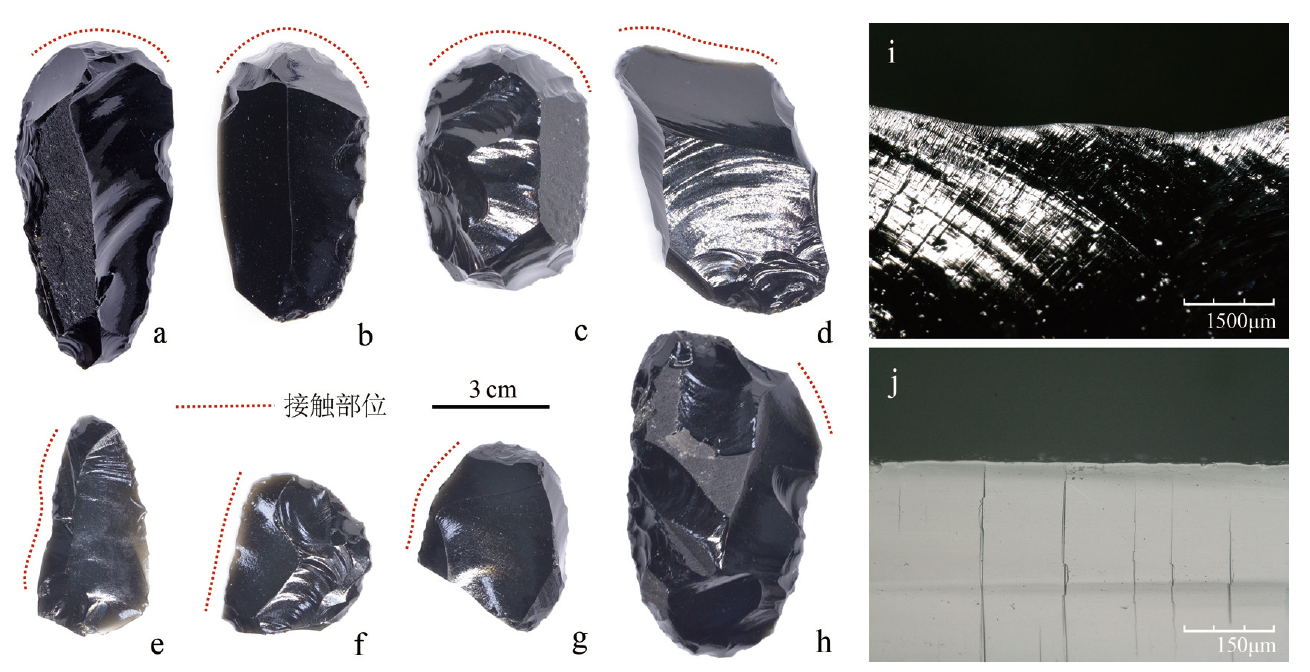

图1 空白对照样本和部分使用标本 a. 002; b. 012; c. 014; d. 004; e. 018; f. 006; g. 007; h. 003; i.空白对照样本(blank control group, 50×);j.空白对照样本(blank control group, 500×)

Fig.1 Blank control groups and part of experimental lithic artifacts

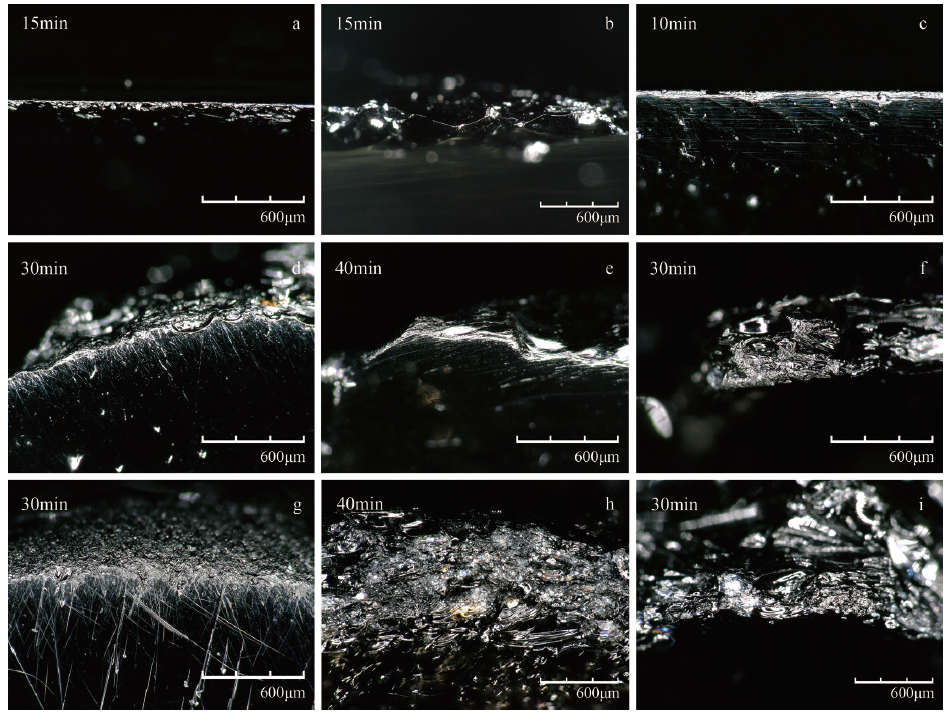

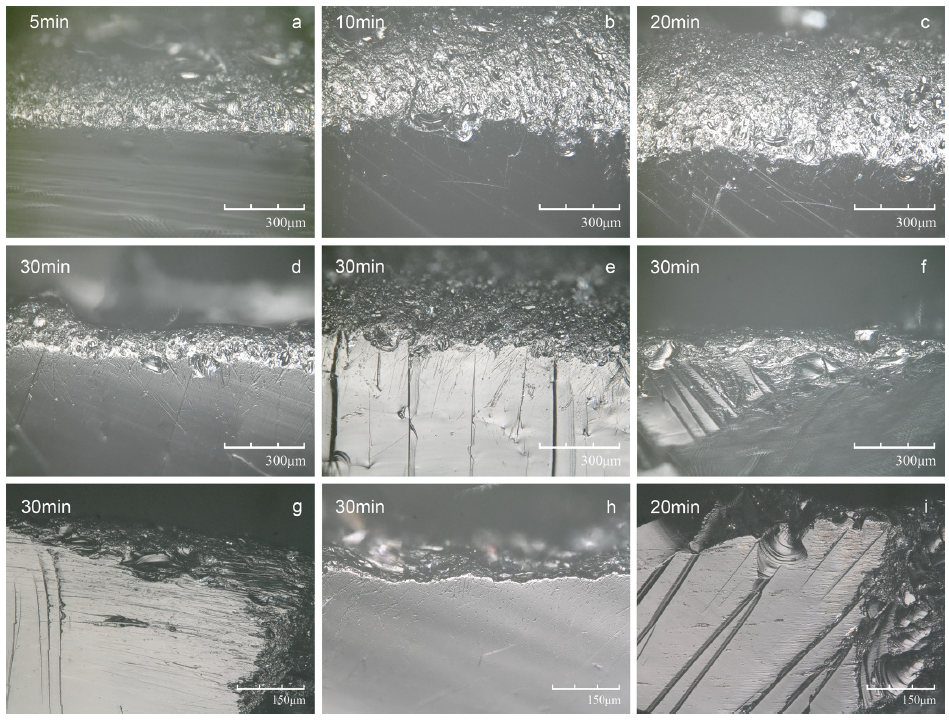

图3 黑曜岩石制品使用磨圆的暗场效果 a. 001,切肉类 cutting meat, 200×;b. 016,肢解剔肉butchery process, 150×;c. 003,切鞣制皮革cutting tanned hide, 200×;d. 002,刮鞣制皮革 scraping tanned hide, 200×;e. 004,切干狗尾草scraping dry foxtail, 200×;f. 005,刮鲜木scraping fresh wood, 200×;g. 009,刮干木 scraping dry wood, 200×;h. 012,刮干燥骨骼scraping dry bone, 150×;i. 014,刮鹿角scraping antler, 150×

Fig.3 Abrasion on obsidian experimental lithic artifacts (Dark Field)

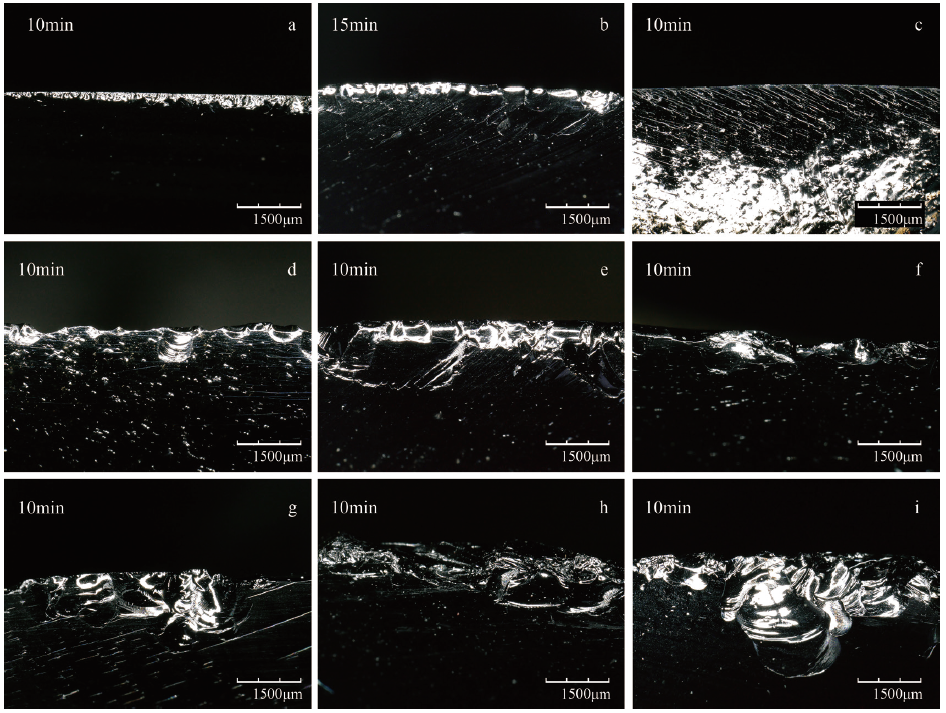

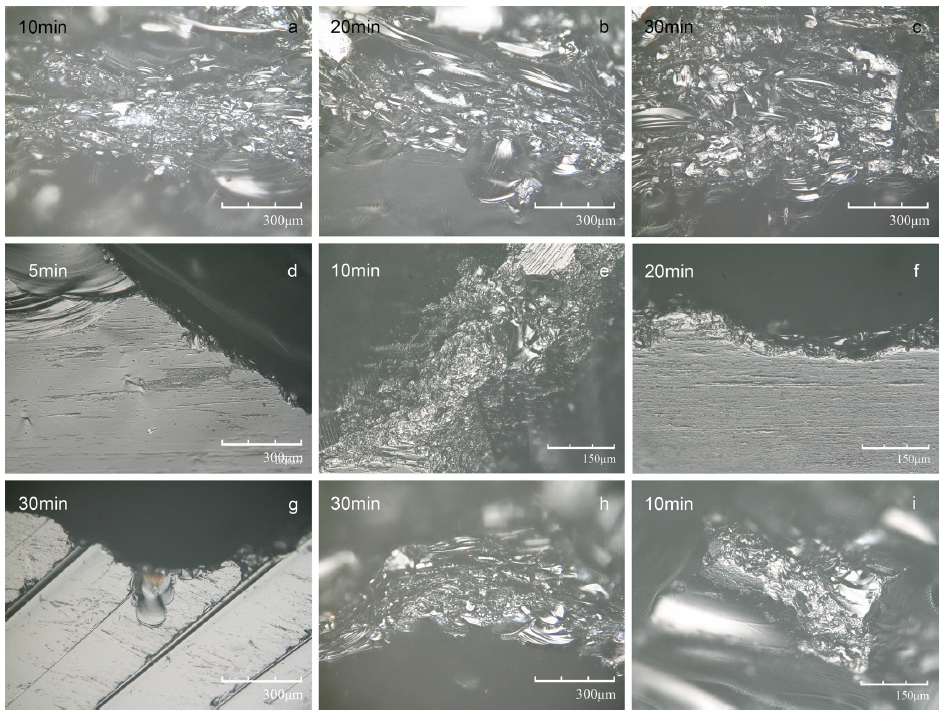

图2 黑曜岩石制品使用片疤的暗场效果 a. 001,切肉类cutting meat, 50×;b. 016,肢解剔肉butchery process, 50×;c. 003,切鞣制皮革 cutting tanned hide, 50×;d. 004,切干狗尾草 cutting dry foxtail, 50×;e. 006,切鲜木cutting fresh wood, 50×;f. 007,切干木cutting dry wood, 50×;g. 010,切新鲜骨骼 cutting fresh bone, 50×;h. 011,切干燥骨骼 cutting dry bone, 50×;i. 013,切鹿角cutting antler, 50×

Fig.2 Micro-scarrings on obsidian experimental lithic artifacts (Dark Field)

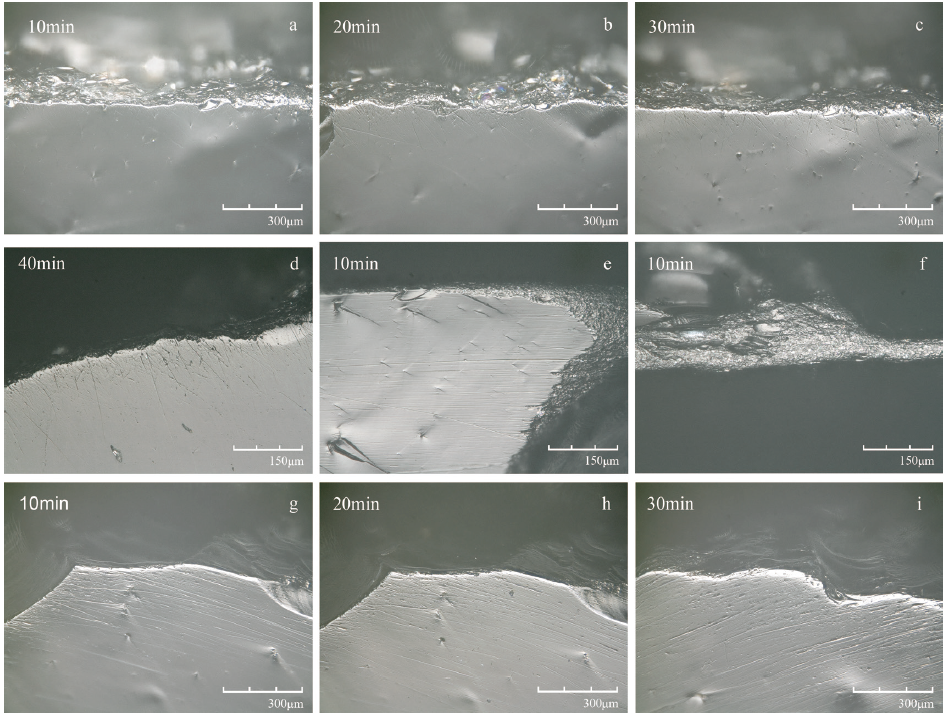

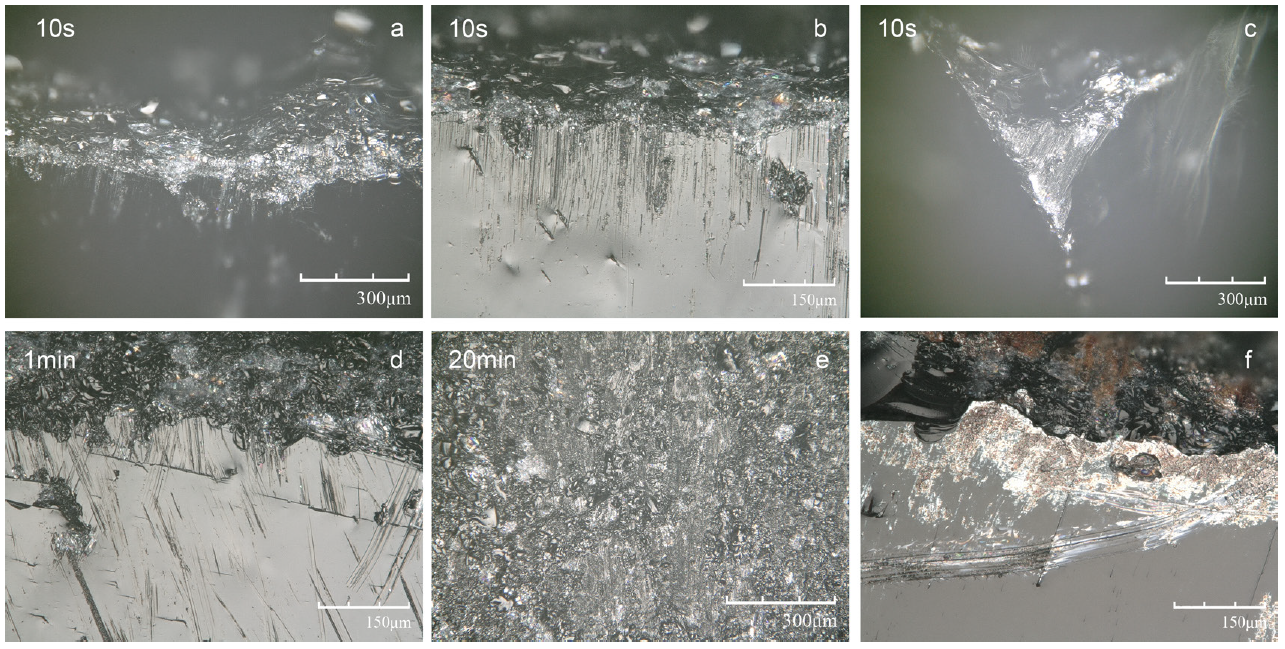

图4 黑曜岩石制品加工鞣制皮革和禾本科植物的微痕(明场) a-c. 002,刮鞣制皮革的光泽和线状痕存在由无到有的阶段型变化the transformation of polish and striation of scraping tanned hide, 300×);d. 002刮鞣制皮革的线状痕the striation of scraping tanned hide, 500×;e. 003切割鞣制皮革的线状痕the striation of cutting tanned hide, 500×;f. 003,切割鞣制皮革的磨圆与光泽 the abrasion and polish of cutting tanned hide, 500×);g-i. 004切割干狗尾草,在很短时间内就形成具有鉴定性意义的光泽与线状痕the well-developed polish and abrasion of cutting foxtail, 300×)

Fig.4 Microwear of processing tanned hide and gramineous on obsidian lithic artifacts (Bright Field)

图5 黑曜岩石制品加工木材的微痕(明场) a. 008,很短时间刮干木的光泽polish of scraping dry wood, 300×;b-d. 009,刮干木在10-30分钟内的光泽无变化 scraping dry wood has no change in polish wear within 10-30 minutes, 300×;e. 009,刮干木的线状痕the striation of scraping dry wood, 300×;f. 007,切干木的磨圆与微小光泽 the abrasion and micro-polish of cutting dry wood, 300×;g. 007,切干木的线状痕the striation of cutting dry wood, 500×;h. 005,刮鲜木的光泽与线状痕the polish and striation of scraping fresh wood, 500×;i. 006,切鲜木的线状痕the striation of cutting fresh wood, 500×

Fig.5 Microwear of wood work on obsidian lithic artifacts (Bright Field)

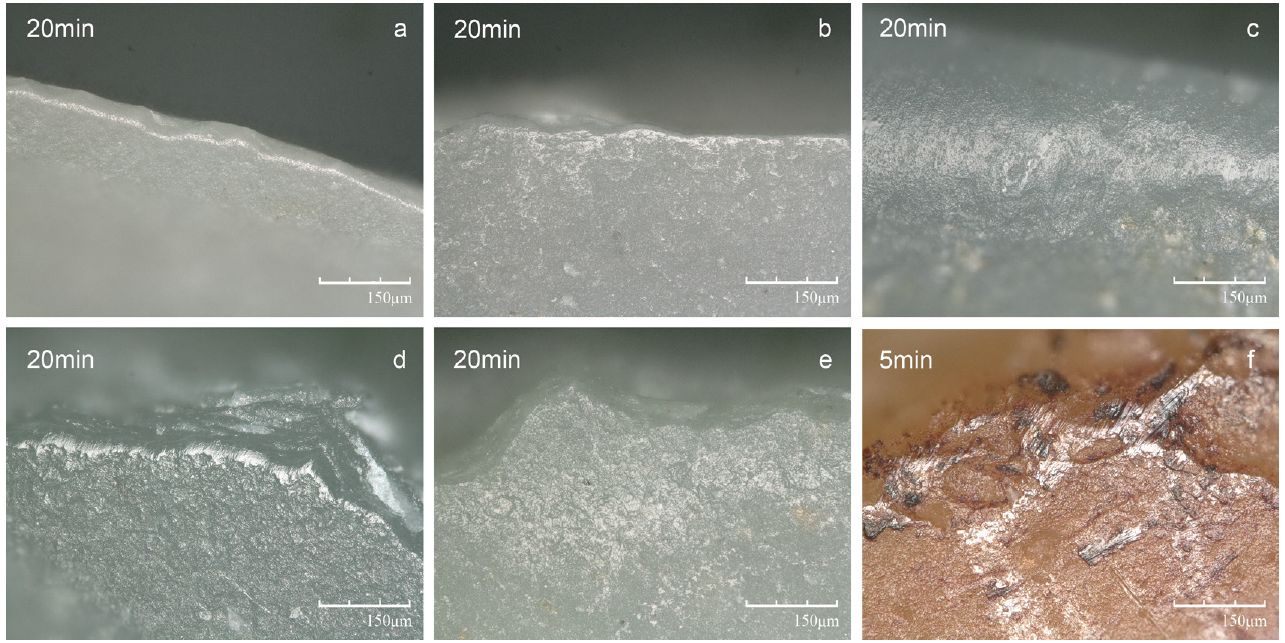

图6 黑曜岩石制品加工骨骼与鹿角的微痕(明场) a-c. 012,刮干燥骨骼的粉碎状破裂随着时间累积逐渐加深 the crush fracture of scraping dry bone deepens with cumulative time, 300×;d. 011,切干燥骨骼的线状痕 the striation of cutting dry bone, 300×;e. 011,切干燥骨骼的微小光泽the micro-polish of cutting dry bone, 500×;f. 010,切鲜骨的线状痕与磨圆 the striation and abrasion of cutting fresh bone, 500×;g. 010,切鲜骨的线状痕the striation of cutting fresh bone, 300×;h. 014,刮鹿角的磨圆与微小光泽the abrasion and micro-polish of scraping antler, 300×;i. 013,切鹿角的磨圆与微小光泽the abrasion and micro-polish of cutting antler, 500×

Fig.6 Microwear of bone and antler work on obsidian lithic artifacts (Bright Field)

图7 黑曜岩石制品接触硬性无机物质的痕迹特征 a. 017硬锤修理hard hammer retouch, 300×;b. 017硬锤修理形成的线状痕the striation of hard hammer retouch, 500×; c. 018修磨悬突形成的线状痕the striation of edge trimming, 250×;d. 018修磨悬突形成的线状痕the striation of edge trimming, 500×; e. 019刃缘磨制edge grounding, 300×;f. 标本015刮赭石的金属光泽metal luster of scraping ochre, 500×

Fig.7 Microwear of processing non-organic material on obsidian lithic artifacts (Bright Field)

图8 燧石实验标本接触各类物质的光泽特征 a. 020,刮鞣制皮革scraping tanned hide, 500×;b. 021,切割干狗尾草 cutting foxtail, 500×;c. 022,刮干木scraping dry wood, 500×; d. 023,刮干骨scraping dry bone,500×;e. 024,刮鹿角 scraping antler, 500×;f. 025,刮赭石scraping ochre, 500×

Fig.8 Polish of processing various material on chert lithics (Bright Field)

| [1] | 陈胜前. 考古学理论的层次问题[J]. 东南文化, 2012, 6: 28-32 |

| [2] | 周振宇. 中国石器实验考古研究概述[J]. 考古, 2020, 6: 77-87 |

| [3] | Chen H. Progress, problem and prospect: An overview of lithic use-wear study in China[J]. Quaternary International, 2020, 535: 58-68 |

| [4] | 万晨晨, 陈全家, 方启, 等. 吉林和龙大洞遗址的调查与研究[J]. 考古学报, 2017, 1: 1-30 |

| [5] | 田川, 徐廷, 关莹, 等. 吉林抚松枫林遗址细石核研究[J]. 人类学学报, 2019, 38(1): 19-32 |

| [6] | 申旭科, 李婷, 张东菊. 中国旧石器原料开发策略的研究进展[J]. 人类学学报, 2023, 42(2): 161-176 |

| [7] | Perreault C, Boulanger MT, Hudson AM, et al. Characterization of obsidian from the Tibetan Plateau by XRF and NAA[J]. Journal of Archaeological Science: Reports, 2016, 5: 392-399 |

| [8] | 侯哲, 赵宇超, 高星, 等. 原料产地对中国东北和韩国旧石器时代晚期黑曜岩石器工业的影响[J]. 人类学学报, 2022, 41(6): 982-993 |

| [9] | 刘爽, 陈全家, 崔剑锋, 等. 吉林省东部旧石器时代晚期遗址黑曜岩制品原料来源探索[J]. 边疆考古研究, 2014, 2: 261-276 |

| [10] | 赵海龙, 徐廷, 马东东. 吉林和龙大洞遗址黑曜岩雕刻器的制作技术与功能[J]. 人类学学报, 2016, 35(4): 537-548 |

| [11] | 徐廷. 高分辨率环境背景下的和龙大洞遗址石器工业研究[D]. 北京: 中国科学院大学博士论文, 2022 |

| [12] | Zhang M. Late Pleistocene and Early Holocene Microblade-based Industries in Northeastern Asia: A Macroecological Approach to Foraging Societies[M]. Forward by Lawrence G. Straus. BAR International Series 3056, Volume 6 of the series Archaeology of East Asia. BAR Publishing, 2021 |

| [13] | 王小庆. 石器使用痕迹显微观察的研究[M]. 北京: 文物出版社, 2008 |

| [14] | 王小庆. 陕西宜川龙王辿遗址第一地点出土石器的微痕观察[J]. 考古, 2017, 11: 100-111 |

| [15] | 高星, 沈辰. 石器微痕分析的考古学实验研究[M]. 北京: 科学出版社, 2008 |

| [16] | 方启. 吉林省东部地区黑曜岩石器微痕研究[D]. 博士研究生毕业论文, 长春: 吉林大学, 2009 |

| [17] | 赵海龙, 徐廷, 马东东. 吉林和龙大洞遗址黑曜岩雕刻器的制作技术与功能[J]. 人类学学报, 2016, 35(4): 537-548 |

| [18] | Setzer TJ. Use-wear experiments with Sardinian obsidian: Determining its function in the Neolithic[D]. University of South Florida, 2004 |

| [19] | Hurcombe L. Use wear analysis and obsidian: Theory, experiments and results[M]. JR. Collis Publications, Dept. of Archaeology and Prehistory, University of Sheffield, 1992 |

| [20] | Kononenko N. Experimental and Archaeological Studies of Use-wear and Residues on Obsidian Artefacts from Papua New Guinea[M]. Technical Report of the Australian Museum, Online, 2011 |

| [21] | Kononenko N, Torrence R, White P. Unexpected uses for obsidian: Experimental replication and use-wear/residue analyses of chopping tools[J]. Journal of Archaeological Science, 2015, 54 |

| [22] | Nesbitt J, Johnson R, Horowitz RA. Was obsidian used for camelid shearing in ancient Peru? An experimental and use-wear study[J]. Ethnoarchaeology, 2019, 1-15 |

| [23] | Stemp WJ, Braswell GA, Helmke CGB, et al. Technological, use-wear, and residue analyses of obsidian blades from Classic Maya burials at Pook's Hill, Belize[J]. Journal of Archaeological Science: Reports, 2019, 26 |

| [24] |

Walton DP. An experimental program for obsidian use-wear analysis in Central Mexican archaeology[J]. Journal of Archaeological Method and Theory, 2019, 26:895-942

doi: 10.1007/s10816-018-9398-7 |

| [25] | Walton DP. Bloodletting in ancient Central Mexico: Using lithic analyses to detect changes in ritual practices and local ontologies[J]. Journal of Archaeological Method Theory, 2021, 28: 274-306 |

| [26] | 方启, 高星, 陈全家. 黑曜岩石器加工木质材料的微痕研究[J]. 边疆考古研究, 2012, 1: 389-403 |

| [27] | 方启, 陈全家. 黑曜岩石器加工兽骨的微痕研究[C].见:中国科学院古脊椎动物与古人类研究所,山东天宇自然博物馆(主编).第十二届中国古脊椎动物学学术年会论文集[A]. 北京: 海洋出版社, 2010, 151-164 |

| [28] | Liu JY, Chen H. An experimental case of wood-working use-wear on quartzite artefacts[J]. Documenta Praehistorica, 2016, 43 |

| [29] | Chen H, Wang J, Lian HR, et al. An experimental case of bone-working usewear on quartzite artifacts[J]. Quaternary International, 2017, 434: 129-137 |

| [30] | 陈虹, 张晓凌, 沈辰. 石制品使用微痕多阶段成形轨迹的实验研究[J]. 人类学学报, 2013, 32(1): 1-18 |

| [31] | Clemente Conte I, Lazuén Fernández T, Astruc L, Rodríguez AC. Use-wear analysis of nonflint lithic raw materials: The cases of Quartz/Quartzite and Obsidian[C]. In: Marreiros JM, Bao JFG, Bicho NF. Use-wear and residue analysis in archaeology, Manuals in Archaeological Method, Theory and Technique[A]. Cham: Springer International Publishing Switzerland, 2015 |

| [32] | 阿子島香. 石器の使用痕[M]. 京都市: ニューサイエンス社,1989 |

| [33] | Juan JI, Niccolò M. Quantitative use-wear analysis of stone tools: Measuring how the intensity of use affects the identification of the worked material[J]. PloS one, 2021, 16(9): e0257266 |

| [34] | Vaughan PC. Use-Wear Analysis of Flaked Stone Tools[M]. Tucson: University of Arizona Press, 1985 |

| [35] | 刘吉颖, 陈虹, 沈易铭. 燧石制品加工竹木材料的微痕实验研究[C].见:陈虹(主编).微研大义:石器微痕研究与思考[A]. 杭州: 浙江大学出版社, 2020, 169-188 |

| [36] | 任思腾. 科学实验中的可重复概念[J]. 自然辩证法通讯, 2020, 42(9): 46-52 |

| [37] | 徐廷, 陈虹, 李尧. 吉林和龙大洞遗址2010年出土雕刻器的初步研究[J]. 人类学学报, 2023, 42(6): 751-763 |

| [38] | 御堂岛正. 黒曜石製石器の実験的痕跡研究[D]. 東京都: 同成社, 2020, 30-78 |

| [1] | 仝广, 李锋, 赵海龙, 闫晓蒙, 高星. 泥河湾盆地火山角砾岩原料的热处理实验[J]. 人类学学报, 2024, 43(01): 81-90. |

| [2] | 徐廷, 陈虹, 李尧. 吉林和龙大洞遗址2010年出土雕刻器的初步研究[J]. 人类学学报, 2023, 42(06): 751-763. |

| [3] | 张乐, 吴秀杰, 张双权. 四川资阳人遗址出土的骨锥[J]. 人类学学报, 2023, 42(01): 1-14. |

| [4] | 侯哲, 赵宇超, 高星, 成春泽. 原料产地对中国东北和韩国旧石器时代晚期黑曜岩石器工业的影响[J]. 人类学学报, 2022, 41(06): 982-993. |

| [5] | 张钰哲, 仝广, 张月书, 胡晓纯, 李锋. 石制品技术分析的盲测实验[J]. 人类学学报, 2022, 41(06): 994-1004. |

| [6] | 崔天兴, 宋炜玮. 激光共聚焦显微镜在微痕定量分析中的应用综述[J]. 人类学学报, 2022, 41(01): 180-192. |

| [7] | 赵海龙, 仝广, 闫晓蒙, 杨淼燃, 谭培阳. 河北泥河湾盆地下卜庄遗址端刮器功能的实验分析[J]. 人类学学报, 2021, 40(04): 600-610. |

| [8] | 卢立群, 董兵, 陈胜前. 中国旧石器时代石球的实验研究[J]. 人类学学报, 2021, 40(04): 587-599. |

| [9] | 黄超, 张双权. X射线衍射技术在烧骨实验研究中的初步应用[J]. 人类学学报, 2021, 40(03): 513-525. |

| [10] | 杨露雅, 朱剑, 岳超龙, 唐际根. 殷墟玉器孔道内部微痕分类辨析[J]. 人类学学报, 2021, 40(02): 249-260. |

| [11] | 华李成, Peter S UNGAR. 牙齿微痕研究在古食性重建中应用的简述[J]. 人类学学报, 2021, 40(02): 292-306. |

| [12] | 崔哲慜, 高星, 夏文婷, 钟巍. 晚更新世东北亚现代人迁移与交流范围的初步研究[J]. 人类学学报, 2021, 40(01): 12-27. |

| [13] | 徐哲, 张晓凌, 裴树文. 射击类带尖石制品使用微痕动态形成过程的实验研究[J]. 人类学学报, 2020, 39(02): 208-222. |

| [14] | 余官玥, 仪明洁, 张晓凌, 陈福友. 水洞沟地区白云岩细石叶的微痕实验研究[J]. 人类学学报, 2020, 39(02): 193-207. |

| [15] | 杨霞;陈虹;王益人. 角页岩雕刻器的微痕实验研究[J]. 人类学学报, 2018, 37(01): 41-52. |

| 阅读次数 | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

全文 331

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

摘要 333

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

京ICP证05002819号-3

京ICP证05002819号-3